Evaluation, Consultation and Validation for Green/Brown Field Projects

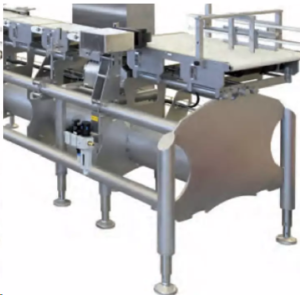

NAFSS sanitary design principles are based on FDA, CFIA, Health Canada, GFTC, GFSI, AIB, 3-A Sanitary Standards, BISSC, European Hygienic Design (EHEDG), National Sanitation Foundation and NAFSS Global Sanitary Design Standards for Food, Beverage, Packaging and Supply-Chain industry. Sanitary design is much more than principles that support an organization food safety program. Sanitary design principles can also be a driver of multi-year operational efficiency gains, compliance with regulatory and customer requirements. Sanitary design is the application of design techniques that allow the timely and effective cleaning of the entire manufacturing asset.

No organization has unlimited capital to spend, but sanitary design principles might be an area that provides a greater benefit from the capital than previously thought, not from an ROI perspective but from an on-going operational perspective that may return substantial savings to the bottom line for many years to come. NAFSS provide sanitary design training to project team including your third-party consultants (civil engineers, architects, electrical engineers etc.). So, is sanitary design a competitive advantage? If your competitor is not investing in sanitary design principles in their capital projects and you are, then the answer is Yes—sanitary design is a competitive advantage!

SECURE your INVESTMENT TODAY, the OPPORTUNITIES are ENDLESS!

10 – 90 Design Process Rule

During the intial 10% of the design process, 90% of the design decisions are made by the project team!

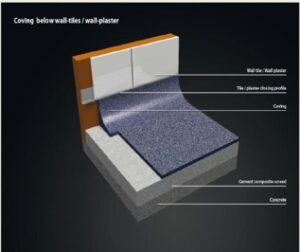

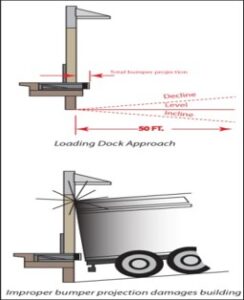

Engineering during design of food and beverage facilities ensures that food safety is built into the facility. Hygienic design principles do not only apply to the direct food contact surfaces but also apply to product zones including indirect contact surfaces, non-product contact surfaces and people all carry a risk of enabling cross-contamination. Hygienic and Sanitary design principles can also be a driver of multi-year operational efficiency gains!

10 Principles of Hygienic and Sanitary Design

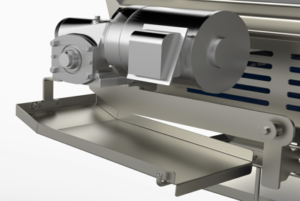

- Cleanability – cleanable to a microbial and allergen-free level

- Construction materials

- Accessibility

- No liquid or material collection

- Hermetic sealing

- No niches, crevices and dead legs

- Operational performance

- Maintenance enclosures

- Hygienic compatibility

- Cleaning verification and validation

Our Services:

- Serving Food

- Beverage

- Packaging

- Distribution Center

- Farms & Green Houses

- Catering & Restaurants

- Hotel Industry